Technology

Never be afraid to push over the limits.

REAL TIME REGULATIONS

Closed Loop Control

The new pressure control allows to manage the injection pressure and correct it in real time. The force regulation via TPQ valve is much slower. With our new TDP valve you can speed up the process, improving OEE.

KEYPOINTS

- Standard machine feature

- Use TDP as standard not TPQ

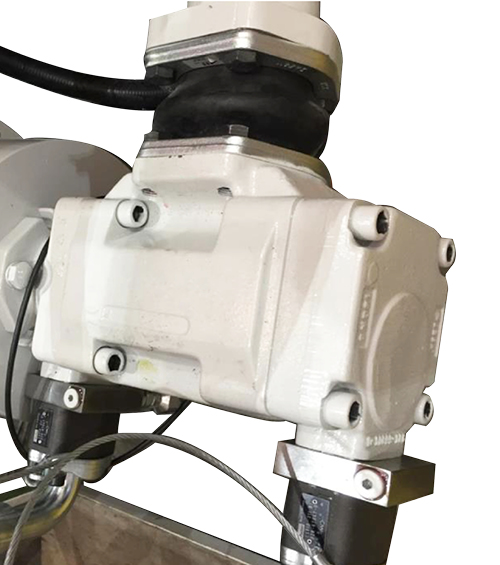

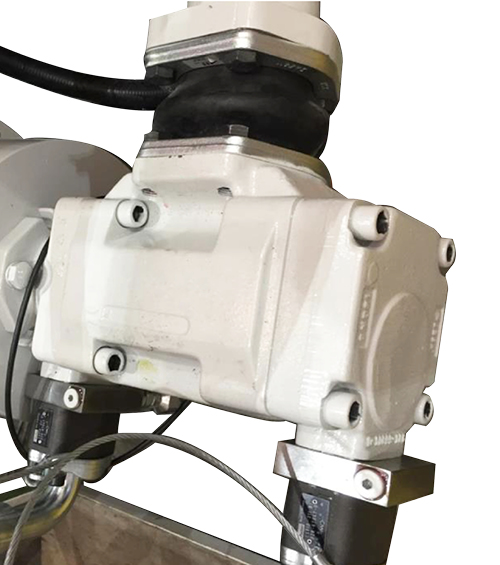

VARIABLE SPEED PUMP MOTORS

Drive Control Pump

The DCP reduces the consumption of the machine.

It’s basically an asynchronous nominal motor that has equipped an encoder that counts the revolutions with an implementation of the software that manages the motor's capacity.

The modified vane pump allows up to 60% energy savings on account and maintenance compared to the classic Hydraulic Drive systems.

KEYPOINTS

Why now AC30V?

- Modern Device concept

- Lower cost

- More DCP-functions

- Supports more fieldbus systems

- Sensorless vector control of induction and permanent magnet motors

- World wide certification

Product concept

- Flexible modular design

- Simple to configure

- High reliability

- 7 sizes

- Power range 0,75 - 200 kW (Output current: 6 - 440A)

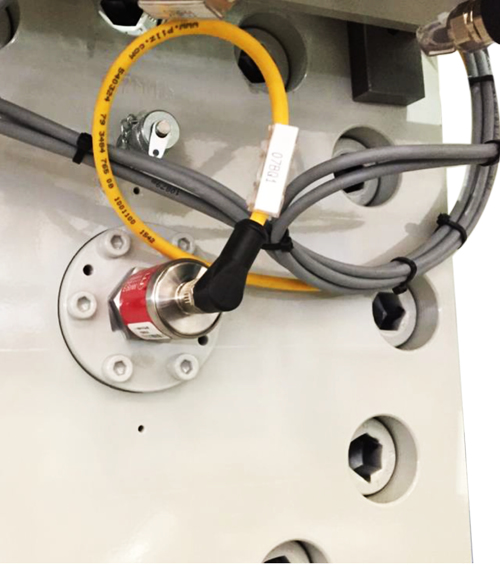

LASER CONTROL ON SLIDING SHOES

Temposonic

The Laser Platen foot measurement reads the consumption of the moving floor skates in real time and give immediate feedback, so you can always maintain the stability of the machine.

KEYPOINTS

- Standard machine feature

- Real time control of platen wear

- Better information for lubrication

- Improved machine life

IMPROVED PERFORMANCE

Analog Fluid Control

The analog fluid control gives us the opportunity to see in real time the fluid level and temperature, fundamental Key Point Indicators to measure and improve machine performance.

KEYPOINTS

- Standard machine feature

- Oil level with leak alarm

- Oil temperature control

AUTOMATED DIE CHANGE

Rapid Die Change

With the Rapid Die Change package all the die change operations are automatic: changing the mold is much easier and safer, and the machine downtime is dramatically decreased.

KEYPOINTS

- Automatic injection Unclamping

- Die Support moving platen

- Die push off cylinders

- Automatic ejection Clamping

- Automatic tie bar removal

- Automatic die height recall

- Die Fluid connection (Staubli)

- Part of the optional rapid die change initiative

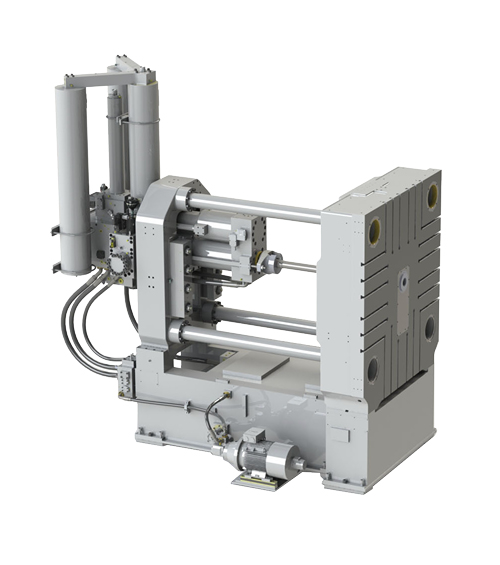

5S© INJECTION SYSTEM

The Injection System

5S is a closed loop regenerative injection with aux servo pump for efficient recharge, that gives you total control of pressure and velocity, with high dynamic force necessary to fill difficult castings, and an incredibile amount of technological enhancements to give you superior results.

KEYPOINTS

- At all speeds (even 10 m/s) the rod side of the injection cylinder remains always pressurized, allowing a perfect control with no cavitation of the hydraulic fluid

- Only one valve for injection speed control, which is inserted in the inlet side of the injection cylinder

- 5S is designed to maximize energy saving and to achieve a long lasting life, in order to improve the eco sustainability of the machine

- An hydraulic cushion is mounted with special design that manages the flow of the hydraulic fluid coming out of the rod side with constant counter pressure

- 5S innovative High Dynamic Force system brings revolutionary stability for injection parameters. This patented regenerative injection is giving first-class repeatability for first and second stage of velocity, while the intensification piston controlled by closed loop gives amazing final pressure

More knowhow, more competence, more satisfaction, less problems and a better productivity efficiency are the expected results.

MORE ABOUT SOLUTIONS

Services

Training courses on IDRA products and technology, seminars on products and process innovation.

Inject Computers

State-of-the-art control systems and machine parameter management: fast, stable, simple, 3D diagnostics.