Designed for high performance and

constant product quality.

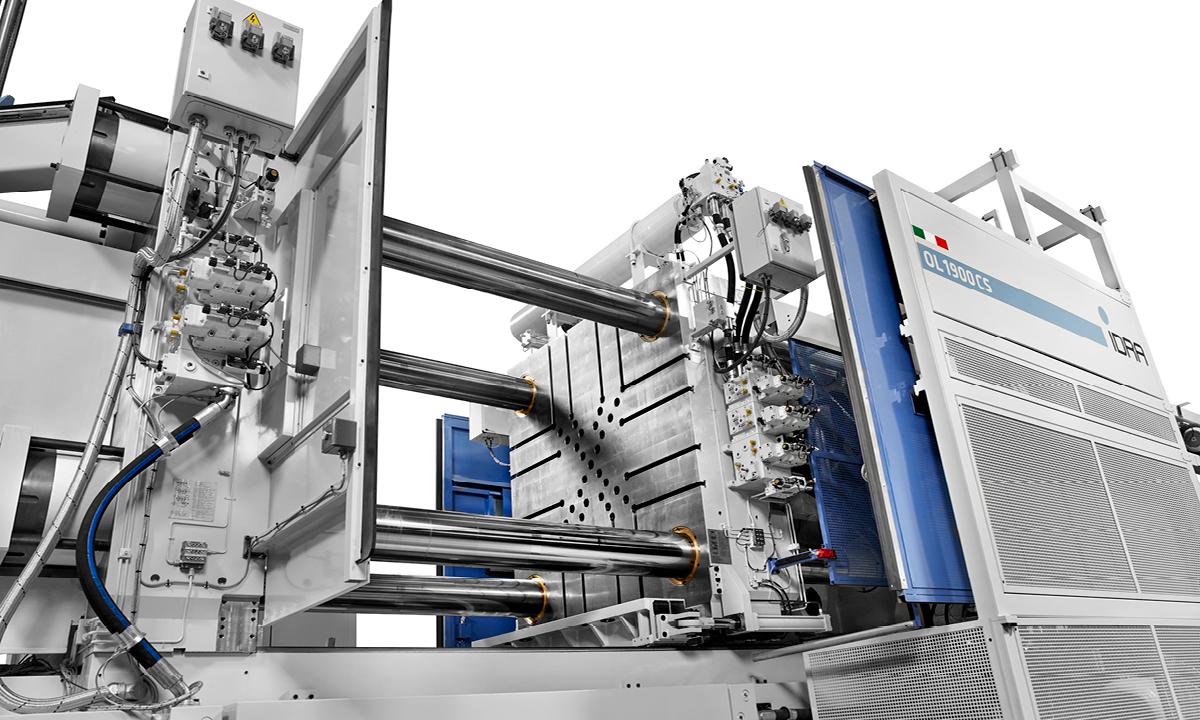

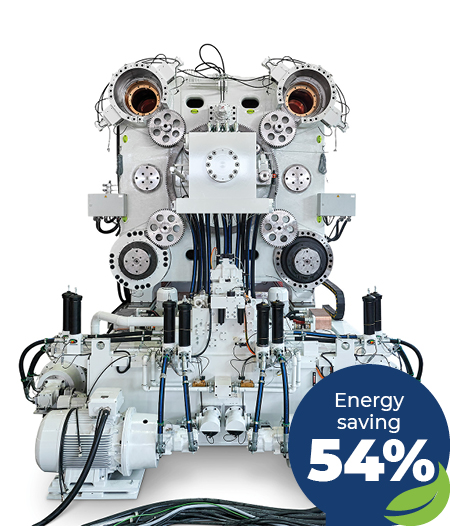

OL CS die casting machines: high performance and consistent quality

IDRA is constantly developing OL CS range, with innovative solutions designed to answer all the latest production requirements.

DOWNLOAD

FORECO, FOREVER

Forward thinking Eco Complimentary Commitment to the world we live in: it's IDRA's mission to work with a green eye on the future, in order lo hand our world to the next generation better than we found it.

Low number of rejects in production.

High efficiency and optimised energy use.

Creating a sustainable foundry environment, right from the design stage.

It contributes to lower production costs.

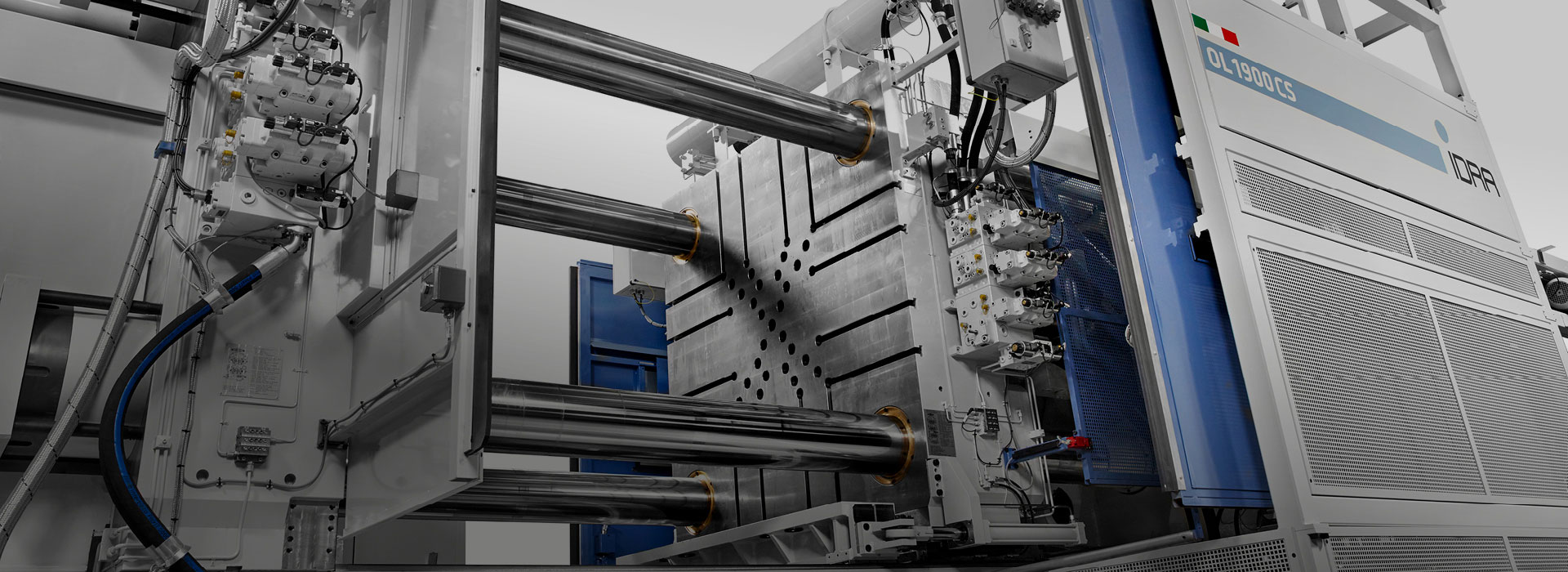

Closed loop pressure control

The new pressure control allows to manage the injection pressure and correct it in real time.

Laser Platen foot measurement

The Laser Platen foot measurement reads the consumption of the moving floor skates in real time and give immediate feedback, so you can always maintain the stability of the machine.

Temposonic measuring

The Temposonic sensor tracks every move of the Intensification Piston, so you can make corrections much faster.

Analog fluid control

The analog fluid control gives us the opportunity to see in real time the fluid level and temperature, fundamental Key Point Indicators to measure and improve machine performance.

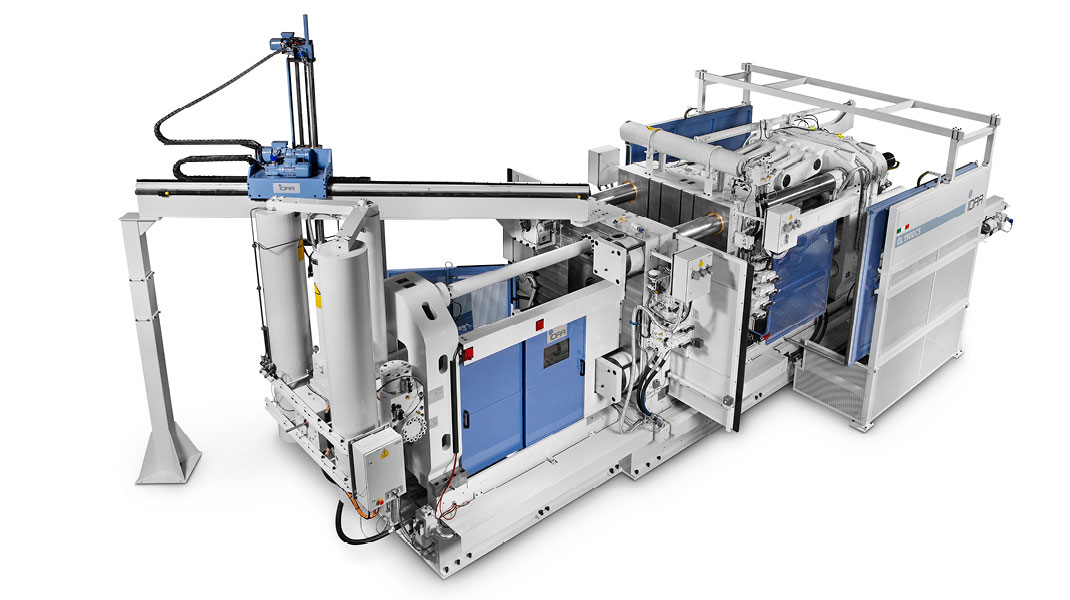

Rapid Die Change

With the Rapid Die Change package all the die change operations are automatic: changing the mold is much easier and safer, and the machine downtime is dramatically decreased.

OVERALL EQUIPMENT EFFECTIVENESS

OEE (Overall Equipment Effectiveness) identifies the percentage of manufacturing time that is truly productive. OL CS improves Quality, Performance and Availability (reducing Stop Time).

SOLIDITY

The compact mechanical structure and robust dimensions have been designed to provide long life and reliability and allow easy and quick maintenance.

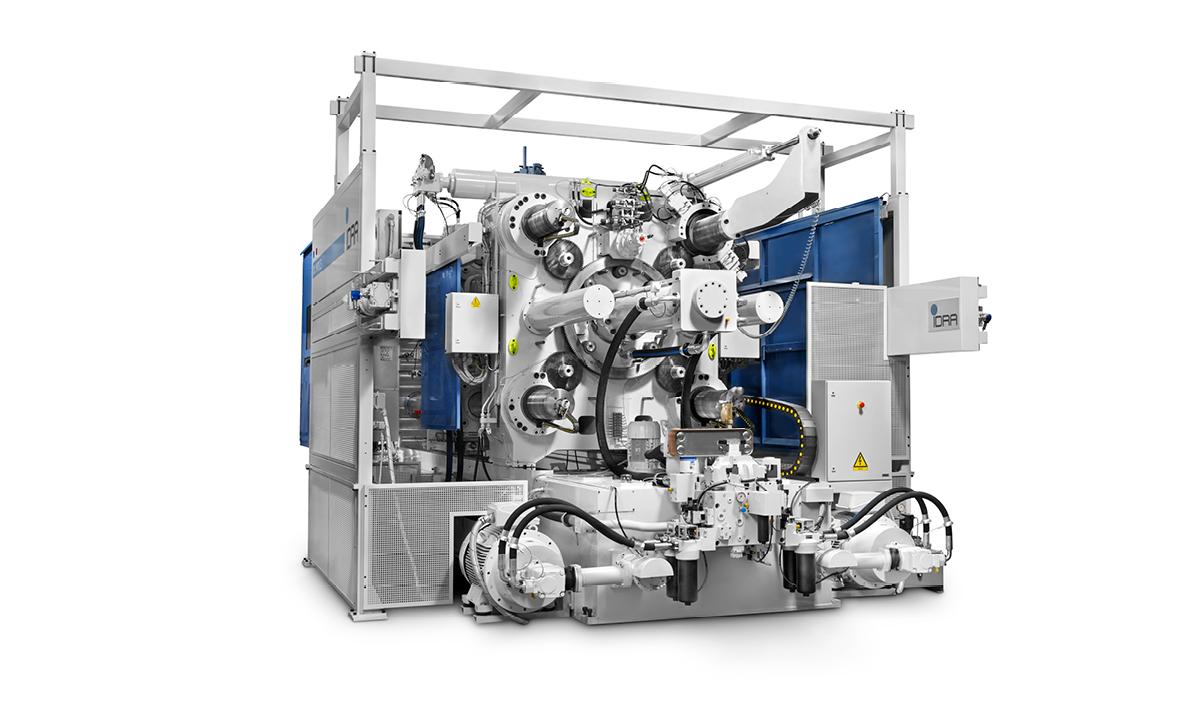

INJECT COMPUTER 3.0

The new award winning Inject Computer 3.0 offers the best in class machine management software, to operate OLCS with great ease of use.

Idra’s new OLS injection is equipped as standard with Parker closed loop meter out proportional valve, which has the same technical characteristics and response time as a servo valve.

The DCP reduces machine consumption. It is basically a nominal asynchronous motor that has an encoder that counts revolutions with a software implementation that manages the motor capacity.

DOWNLOAD

VIDEOGALLERY

00:00 Welcome

1:09 Intro

1:40 Oil Pump

3:12 5S Injections

4:20 Plate

5:03 Guarding System

6:07 The New Giga Press

6:45 Outro/ Goodbye